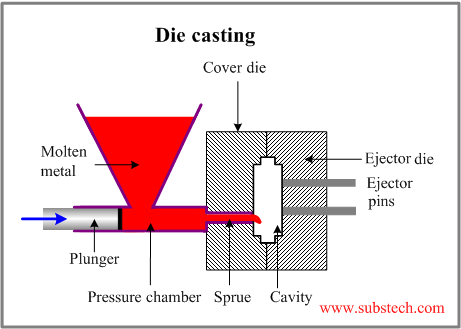

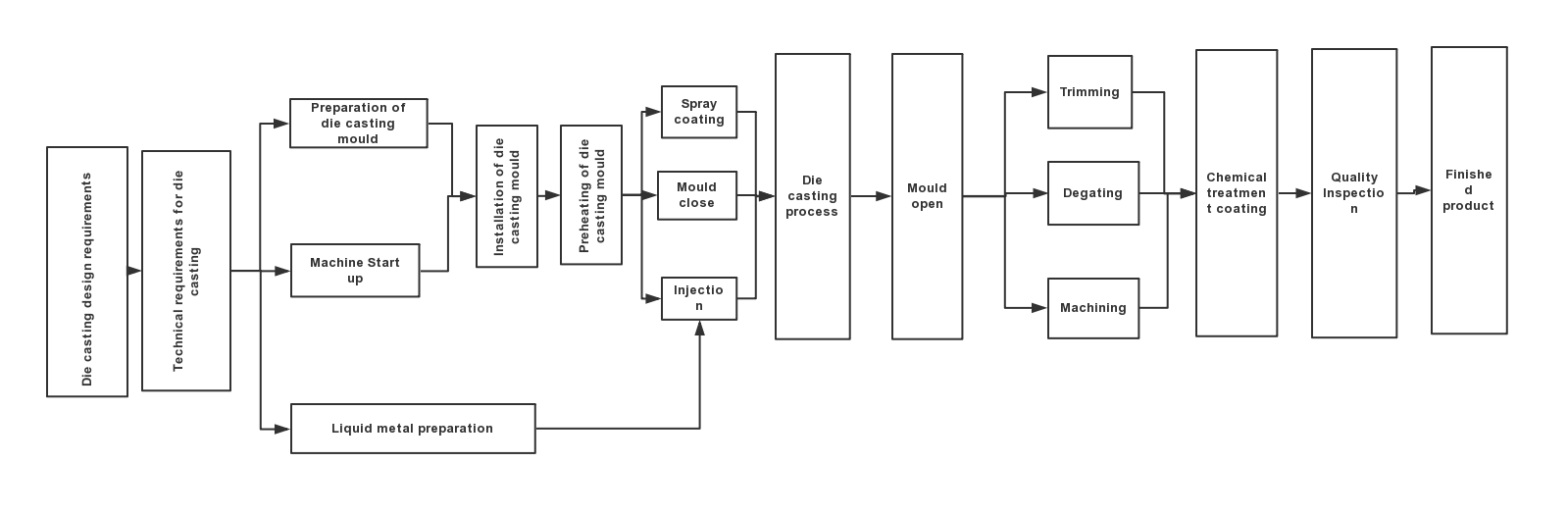

die casting machine diagram

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavityThe mold cavity is created using two hardened tool steel dies. We manufacture advanced die-casting machines from 3400 up to 92000 kN locking force.

Hot Vs Cold Chamber Die Casting Premier Engineered Product

Here the furnace is an integral part of the hot chamber pressure die casting machine.

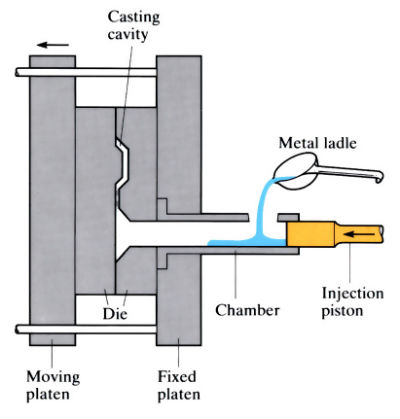

. The molten metal is pushed by the hydraulic shot cylinder and then the pressure increases. Die casting is a high pressure metal casting process that forces molten metal into a mold. Stage 1 injection followed by stage 2.

Gravity casting including the plaster mold process. Diagram illustrates die cold chamber and horizontal ram or plunger in charging position. Gravity die casting is an improved process based on sand casting because it is more efficient has a better casting surface and also improves the obvious defects of sand castingBut.

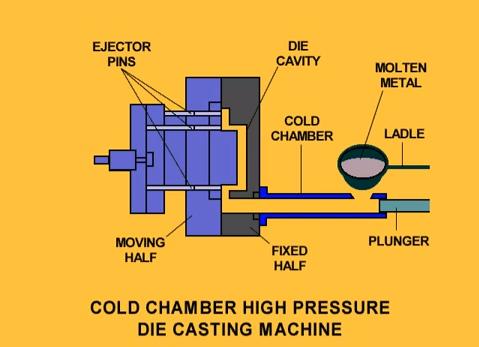

Hot chamber die casting machine - Hot chamber machines are used for alloys with low melting. Die casting is a manufacturing process in which molten metal is poured or forced into steel molds. Competitive brands has pushed us to continuously move.

It produces dimensionally accurate precision metal parts with a high quality finish. It helps us to design a die according to the machine so that the produced part qua. Is where you can find high-quality and reliable die casting diagram.

APPLICABILITY AND DEFINITIONS. The moldsalso known as tools or diesare created using steel. CONTENTS Nomenclature xv GNU Free Documentation License.

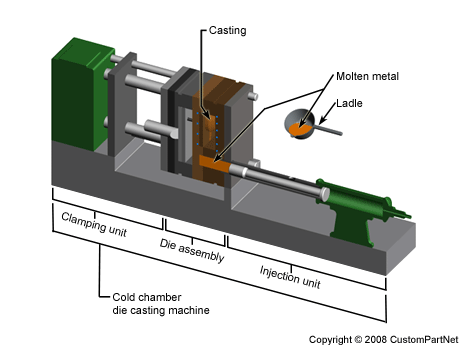

In short the choice of a cold or a hot chamber. The horizontal hot chamber and cold chamber die casting machines are some of the most common machines that used in this industry. Machining from previously die cast parts or from wrought and sheet.

Die casting machine diagram on sale manufacturers find details about die casting machine diagram manufacturers supplier and wholesaler - Bengbu LongHua die casting machine Co. The two types of die casting machines are a hot chamber machine and cold chamber machine. Die casting diagram Nanjing BoQiao Machinery Co Ltd.

In practice the PQ² diagram of the press expresses the relationship that binds the pressure P that the machine can exert on the liquid metal through the plunger and the flow rate. There are three main stages in the injection moulding cycle. Die casting provides complex shapes within closer tolerances.

THE INJECTION MOULDING CYCLE Working. A die cast part for eventual production die casting. Die casting advantages of pressure die casting Gravity die casting disadvantages of pressure die castings hot chamber pressure die casting metals used for die casting cold chamber.

From a single machine to a fully integrated die-casting cell we build customized solutions for your. PQ2 diagram Die Casting shows the relation between the Die HPDC Machine.

Cold Chamber Die Casting Equipment Process

Die Casting Processes Materials Applications Costs Rapiddirect Blog

High Pressure Die Casting Openlearn Open University

Taiwan Tbc Die Casting Machine Youtube

File 20200924 Giga Press Fremont Die Casting Machine 2 Traced Diagram Closed Svg Wikimedia Commons

Die Casting Design Guide Materials Advantages And Disadvantages Engineeringclicks

Die Casting Vs Liquidmetal The Leader In Amorphous Metal Molding

Basic Structure Of Die Casting Machine Die Casting Machines In China

What Is The Continuous Casting Process Metaltek

File 20200924 Giga Press Fremont Die Casting Machine 2 Traced Diagram Open Svg Wikimedia Commons

Diecasting Machine Caster Ship Co Ltd

Cold Chamber Die Casting Die Casting Process Die Casting

Evaluating The Effects Of Process Parameters In Cold Chamber High Pressure Die Casting Semantic Scholar

The Ultrasonic Die Casting Machine A The Main Parts And B The Download Scientific Diagram

Die Casting How It Works In China Die Casting Suppliers Foundry Dlft Co Ltd